As the automotive industry continues to evolve, the demand for custom tubing components has become increasingly vital in enhancing vehicle performance and functionality.

From structural support to exhaust system clearance, the utilization of high-quality and durable materials is paramount in meeting the specific requirements of racing cars, motorbikes, and restoration projects.

However, the intricacies of custom tube fabrication and the materials used in this process are often overlooked.

Understanding the significance of these components and their applications in various automotive sectors is crucial for automotive designers and enthusiasts alike.

Key Takeaways

- Tubing components for automotive and motorsports are custom-made for structural support and optimal performance.

- Various materials such as stainless steel, aluminium, titanium, and copper-based alloys are used for specific applications.

- The tubing is strong, corrosion-resistant, and suitable for high-speed trains, architectural purposes, and marine applications.

- There are a variety of tube profiles available for architectural purposes, and expert advice, quotes, and free samples can be obtained for customization.

What are Automotive custom tubes

Automotive custom tubes are specialized tubular components designed and fabricated to meet the precise structural and performance requirements of vehicles in the automotive and motorsports industries. These tubes are custom-designed to deliver optimal performance and cater to the specific needs of automotive applications.

There are various advantages of custom tube fabrication, including the ability to create one-off pieces or mass-produced components tailored to the exact specifications of the vehicle. Different types of automotive custom tubes are available, such as flat-sided oval-shaped tubes for exhaust system clearance and structural support for racing cars.

When designing custom tubes, considerations such as material selection, dimensions, and performance goals are paramount to ensure that the final product meets the desired standards. The benefits of using custom tubes in automotive applications are numerous, including improved strength-to-weight ratios, corrosion resistance, and the ability to withstand extreme temperatures, making them ideal for exhaust systems.

However, challenges in manufacturing automotive custom tubes may arise due to the need for precision engineering, specialized tooling, and flexibility in fabrication to accommodate unique designs and specifications.

Material used for custom tubes in the Automotive industry

Custom tubes in the automotive industry are commonly fabricated using a range of materials selected for their specific properties and performance characteristics. The choice of material significantly impacts the performance and durability of custom tubes in automotive applications. Different types of alloys are used in custom tubes, each offering specific benefits. For instance, stainless steel is widely favored for its exceptional corrosion resistance, making it ideal for exhaust systems due to its ability to withstand extreme temperatures and harsh environmental conditions. The table below provides an overview of the different materials used in automotive custom tubes and their respective advantages.

| Material | Advantages |

|---|---|

| Stainless Steel | Excellent corrosion resistance |

| Aluminum | Lightweight and high strength-to-weight ratio |

| Titanium | Superior strength and heat resistance |

| Copper-based Alloys | Good thermal conductivity and corrosion resistance |

| Advanced Alloys | Enhanced performance and durability |

Advances in material technology have led to the development of custom tubes with improved strength, durability, and resistance to environmental factors, contributing to the overall performance and longevity of automotive components. The selection of the most suitable material is crucial in ensuring the optimal performance and reliability of custom tubes in the automotive industry.

Automotive and transport-related applications

When considering automotive and transport-related applications, it is crucial to examine the various components that custom tubes are used for.

These components include suspension components, exhaust system components, intake, and engine components, as well as structural components, cargo, and seating components.

Each of these applications demands specific design and material considerations to ensure optimal performance and durability in the automotive and transport industries.

Suspension Components

Suspension components play a critical role in ensuring the stability, handling, and overall performance of automotive and transport-related applications. These components offer performance enhancements, customization options, and handling improvements, particularly in racing applications. Suspension tuning is crucial for optimizing the vehicle’s dynamics, and custom tubes are integral to achieving this. The table below illustrates various suspension components used in automotive and transport-related applications.

| Suspension Components | Function |

|---|---|

| Suspension wishbones | Support and mobility |

| Support arms for car boots | Structural support |

| Cross tubes | Reinforcement |

| Support tubes for chassis | Stability and strength |

| Cant rails, skirts, and trims | Aerodynamics and aesthetics |

Exhaust System Components

The design and functionality of exhaust system components play a crucial role in optimizing the performance and emissions control of automotive and transport-related applications. When it comes to automotive exhaust systems, custom fabrication, and aftermarket options are essential for performance upgrades and exhaust noise reduction.

The following are key considerations for exhaust system components:

- Custom fabrication: Tailoring exhaust components to specific vehicle requirements.

- Performance upgrades: Enhancing exhaust system efficiency and power output.

- Aftermarket options: Providing a range of exhaust components for customization and replacement.

In the automotive industry, exhaust systems are integral to vehicle performance, and the availability of custom fabrication and aftermarket options allows for tailored solutions to meet specific requirements.

Intake and Engine Components

Intake and engine components are vital elements of automotive and transport-related applications. They encompass inlet manifolds, radiators, diesel injection components, shafts, and instrument panel tubes.

In the automotive industry, intake manifold design plays a crucial role in engine component customization. It aims for performance enhancements, ensuring optimal airflow and fuel mixture delivery to the engine.

Custom tube fabrication is integral to meet the evolving automotive industry trends. It ensures the efficiency and power output of intake and engine components. The demand for custom tubes in these components is driven by the pursuit of enhanced efficiency and power output.

As the automotive landscape continues to evolve, precision engineering and innovative materials are shaping the future of intake and engine component design. This drives the need for advanced custom tube solutions that can meet the industry’s exacting requirements.

Structural Components

Utilizing advanced fabrication techniques, the structural components of automotive and transport-related applications serve as integral support systems, ensuring the structural integrity and safety of the vehicles.

Automotive Tube Fabrication:

- Customized Structural Tubes: Tailored to specific vehicle requirements.

- Automotive Tube Applications: Used in headrest armatures, internal structural frameworks, roof rails, and bumper edging.

- Tube Bending Techniques: Advanced techniques employed to create complex shapes for seamless integration.

The automotive industry heavily relies on advanced tube manufacturing for bespoke components and prototypes, employing materials like stainless steel and alloys to enhance strength, durability, and corrosion resistance. Precision tube laser cutting and in-house steel tube services further optimize the production of structural components, ensuring high-quality, reliable automotive solutions.

Cargo and Seating Components

In automotive and transport-related applications, the fabrication and integration of cargo and seating components are crucial for ensuring functional and efficient vehicle design.

Cargo storage requires custom fabrication to optimize weight and material selection for durability. Seating design necessitates meticulous attention to weight optimization while ensuring safety and comfort.

Custom tubes play a vital role in the construction of seat assemblies and mechanisms, providing strength and support. Precision tube laser cutting is utilized for aftermarket automotive parts, ensuring accurate and clean cuts for cargo and seating components.

Additionally, custom in-house steel tube services offer bending and cutting capabilities to meet specific cargo and seating requirements. These components are fundamental for delivering high-quality, durable, and safe automotive and transport solutions.

Automotive Frames

The fabrication and integration of cargo and seating components in automotive and transport-related applications are fundamental for ensuring functional and efficient vehicle design, and this same attention to detail and precision extends to the construction of race car and motorcycle frames.

Automotive tube manufacturing involves the use of high-quality materials and precise production techniques to ensure the structural integrity of frames.

Tube welding techniques are crucial for joining frame components securely, contributing to the overall safety and performance of the vehicle.

Tube forming processes and tube bending machines play a vital role in shaping the tubes to meet specific design requirements, ensuring optimal fit and functionality.

These processes are essential for producing robust and reliable automotive frames, meeting the stringent quality and safety standards of the industry. Tube inspection methods further guarantee the durability and performance of the frames.

Miscellaneous

Employing advanced fabrication techniques and high-quality materials is essential in the production of various components such as shift levers and steering columns for automotive and transport-related applications.

Custom tube manufacturing plays a crucial role in creating these components, utilizing precise automotive tube fabrication and tube bending techniques. Steel tube finishing ensures durability and corrosion resistance, meeting the demanding requirements of automotive applications.

Advancements in tube laser cutting technology further enhance the production process, allowing for accurate and clean cuts in the fabrication of aftermarket automotive parts, such as gear shafts and tie rods. These cutting-edge techniques contribute to the safe functioning of finished assemblies.

As an integral part of the automotive industry, these advancements are vital for producing top-quality components with exceptional precision and performance.

Tubing used in automotive and transport applications

Tubing used in automotive and transport applications encompasses a range of specialized designs to meet specific requirements.

The use of oval tube, flat-sided oval tube, D-shaped tube, radiused square tube, and twisted square tube caters to diverse structural and functional needs in automotive and transport applications.

Each of these tube profiles offers unique advantages, such as strength, water resistance, and aesthetic impact, ensuring the suitability of the tubing for various automotive and transport-related uses.

Oval Tube

Utilizing its ergonomic shape and seamless form, the iconic oval tube design offers unparalleled potential for automotive and transport applications.

The oval tube finds various applications in architecture, providing strength and aesthetic appeal to handrails and balustrades. In the marine industry, its advantages are leveraged for boat railings due to its resistance to corrosion and weathering.

Customization options for oval tubes include a wide range of sizes, materials, and finishes, catering to specific design requirements. Joining techniques for oval tubes involve welding or dry joining with specially designed joiners, ensuring uncompromising and seamless forms for handrails and balustrades.

Additionally, oval tube fabrication services offer extensive expertise in shaping, bending, and fabricating these tubes, ensuring high-quality and customized solutions for automotive and transport needs.

Flat sided Oval Tube

The ergonomic and seamless form of the iconic oval tube design has found applications in architecture and the marine industry. This design has paved the way for the utilization of flat-sided oval tubing in automotive and transport applications. Flat-sided oval tubing offers easier fabrication and maintenance, making it suitable for architectural designs, handrails, and automotive applications.

It provides a maintenance advantage due to its contoured profile and is available in stainless steel, copper, brass, bronze, and aluminum. Notably, flat-sided oval tubes are up to 54% stronger than standard round steel tubing, offering enhanced structural integrity. Joining systems are available, enhancing the aesthetic appeal and structural integrity of D-shaped tubes.

Additionally, customization options for flat-sided oval tubes include tailored tooling for new sizes and tube manipulation services like flaring, welding, and bending.

D shaped Tube

D-shaped tube, commonly used in automotive and transport applications, offers ergonomic design and structural integrity for a variety of engineering projects.

D-shaped Tube Applications

Benefits of D Shaped Tube

- Ergonomically designed for gripping by hand

- Ideal for external handrails in public buildings, yachts, and cruise liners

- Suitable for housing electronic components and cables

Customizing D Shaped Tube

- Custom-made in various sizes

- Can be made from stainless steel, aluminium, brass, copper, and cupronickel

- Glazing channel can be attached through welding or threaded inserts

D Shaped Tube in Architecture and Marine Industry

- Stops water ingress and reduces corrosion

- Suitable for external handrails in ramps, stairs, and balustrades

- Alternative to teak wood railings on boats

Radiused Square Tube

Radiused square tubing, commonly utilized in automotive and transport applications, offers exceptional strength and structural integrity for a variety of engineering projects. When compared to round tubes, radiused square tubing exhibits a 54% increase in deflection capacity, making it ideal for bending and large radius bends in automotive applications.

This tubing’s impressive strength makes it suitable for various automotive components, including chassis and structural supports. The choice of material is crucial, with options such as stainless steel 304L, 316L, titanium, aluminum, or copper, each offering distinct advantages.

Case studies have demonstrated successful integration of radiused square tubing in automotive projects, showcasing its versatility and durability. As automotive design trends continue to evolve, the incorporation of radiused square tubing presents an opportunity to enhance both performance and aesthetics in vehicle construction.

Twisted Square Tube

In automotive and transport applications, the twisted square tube offers superior strength and rigidity, making it a versatile and cost-effective choice for a range of engineering projects.

The twisted square tube has various applications, including:

Twisted square tube applications in architecture: Suitable for architectural designs due to its aesthetic appeal and structural integrity.

Twisted square tube in decorative metalwork: Ideal for creating decorative elements in metalwork due to its unique twisted design.

Twisted square tube in art installations: Used in high-profile art installations due to its sculptural qualities and aesthetic appeal.

This tubing is also commonly utilized in interior design and sculpture, showcasing its diverse range of applications in the automotive and transport industries.

Twisted Oval Tube

The twisted oval tube, commonly utilized in automotive and transport applications, offers a unique combination of strength, versatility, and aesthetic appeal. It finds applications in architecture, particularly in handrail design, where its advantages include multiple customization options for decorative projects.

When compared to other decorative metal profiles, the twisted oval tube stands out for its distinctive properties and modern interior design trends. Crafted from various metals such as stainless steel, copper, brass, bronze, and cupronickel, this tubing can be customized with finishes ranging from highly reflective super marine polish to contemporary satin finish.

Furthermore, engineers can create continuous twists or looser twists, and straight sections of tubing can be left at either end for easier joining, enhancing its suitability for various industrial and architectural uses.

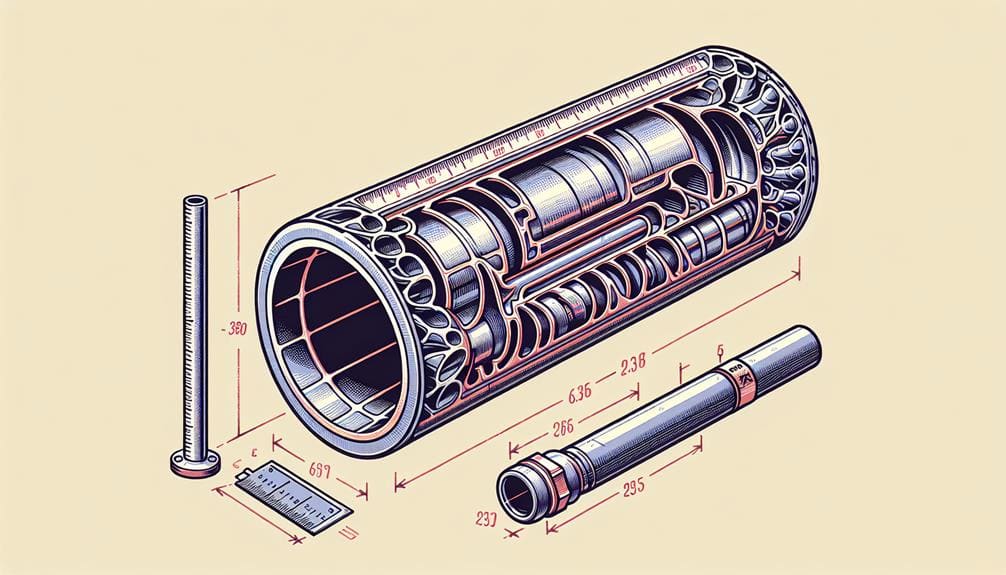

DOM Mechanical Round Steel Tubing

The twisted oval tube, commonly employed in architectural and transport applications, transitions seamlessly into the discussion of the DOM Mechanical Round Steel Tubing, which is extensively utilized in automotive and transport settings.

DOM Mechanical Round Steel Tubing

Superior Performance

- DOM tubing offers high tensile and yield strength for demanding automotive applications.

- Provides excellent machinability and a smooth surface finish, enhancing automotive tube performance.

- Cold finishing process ensures dimensional accuracy and consistent mechanical properties.

Custom Manufacturing

- Tailored tube fabrication techniques cater to specific automotive design considerations.

- Enables the production of precise and custom automotive steel tubes for varied applications.

- Offers flexibility in creating tubes for diverse automotive components and systems.

Design Considerations

- DOM tubing allows for intricate and durable automotive tube designs, crucial for structural integrity.

- Consistent mechanical properties support the development of reliable automotive components.

- Enhances automotive safety and performance through precision engineering and manufacturing.

Tube vs Pipe in the automotive industry

Steel tubing and piping play crucial roles in the automotive industry, each serving distinct purposes due to their inherent structural and functional characteristics.

When it comes to tube manufacturing processes, custom tubes offer advantages in automotive applications due to their flexibility, allowing for bespoke designs and tailored solutions. Additionally, specific tube welding techniques for the automotive industry ensure the integrity and durability of the components.

The impact of tube dimensions on automotive performance is significant, as the size and shape of the tubing directly influence the vehicle’s weight, aerodynamics, and overall efficiency.

Furthermore, cost considerations of using custom tubes in automotive manufacturing are essential, as the material, fabrication, and installation expenses must align with the desired performance and quality standards. Therefore, automotive manufacturers carefully evaluate these factors to achieve optimal results while maintaining cost-efficiency.

Custom Steel tube services in the automotive industry

Custom steel tube services in the automotive industry encompass a range of crucial operations. These include steel tube bending, band saw cutting, galvanizing steel tube, sandblasting steel, and powder coating & painting.

These services are essential for fabricating automotive components with precision and durability. By leveraging these custom steel tube services, automotive manufacturers can ensure the reliable performance and longevity of their vehicles.

Steel Tube Bending

In the automotive industry, precision steel tube bending plays a crucial role in the fabrication of customized components for various applications, including exhaust systems, chassis, and structural supports.

Steel tube fabrication for automotive tube manufacturing offers benefits such as superior strength, corrosion resistance, and the ability to withstand extreme temperatures.

Custom tube applications in the automotive sector rely on advanced bending techniques to achieve precise and durable components.

Steel Tube Bending Techniques

Mandrel Bending: Ensures uniform diameter and prevents crinkling or collapsing.

Heat Induction Bending: Allows for bending without any wrinkles or deformation.

Compression Bending: Ideal for creating tight bends without distortion.

Band Saw Cutting

Precision band saw cutting is a crucial aspect of custom steel tube services in the automotive industry, complementing the advanced bending techniques utilized in fabrication processes. Band saw cutting ensures accurate and clean cuts, meeting the exact specifications required for automotive components.

This process is essential for creating precise lengths and angles in steel tubes, enabling the production of tailored parts for various automotive applications. Additionally, band saw cutting is a fundamental step before other finishing processes such as galvanizing, precision tube laser cutting, and powder coating & painting.

The precision and efficiency of band saw cutting contribute significantly to the overall quality and functionality of the steel tubing used in automotive manufacturing, making it a vital component of the production process.

Galvanizing Steel Tube

Galvanizing steel tube is an essential process in the automotive industry. It provides durable corrosion resistance and ensures longevity for various components used in automotive manufacturing.

The galvanizing process involves coating the steel tube with a layer of zinc. This offers several benefits such as superior corrosion protection, extended service life, and minimal maintenance requirements.

Galvanized steel is extensively utilized in the automotive industry. It is known for its exceptional resistance to rust and corrosion, making it ideal for applications exposed to harsh environmental conditions.

In comparison to other coating methods, galvanizing provides a robust and reliable protective layer. It outperforms alternative options and guarantees the integrity and durability of critical components used in automotive manufacturing.

Ultimately, the utilization of galvanized steel in automotive manufacturing ensures optimal performance and safety on the road.

Sandblasting Steel

Sandblasting steel is a critical process within the realm of custom steel tube services in the automotive industry. It ensures the preparation of surfaces for optimal coating adhesion and long-lasting durability.

Sandblasting techniques involve the use of abrasive blasting methods to remove contaminants and create a clean, roughened surface. This is essential for effective coating adhesion. The surface preparation achieved through sandblasting is crucial for achieving corrosion protection and enhancing the durability of custom steel tubes.

The finishing processes following sandblasting are pivotal in determining the final quality and performance of the tubes. By employing precise sandblasting methods, automotive professionals ensure that the steel tubes meet the highest standards for functionality and longevity in various automotive applications.

Powder Coating & Painting

In the automotive industry, the process of powder coating and painting plays a crucial role in enhancing the durability, protection, and aesthetic appeal of custom steel tubes. When considering custom tube finishes, automotive painting techniques, and tube surface preparation, it’s essential to understand the benefits of powder coating, which include:

Enhanced Durability: Powder coating provides a tough, long-lasting finish that is more resistant to chips, scratches, and fading compared to traditional liquid paints.

Environmental Benefits: This method produces less hazardous waste and emits virtually no volatile organic compounds (VOCs), contributing to a more eco-friendly production process.

Versatile Aesthetic Options: Powder coating allows for a wide range of color options and finishes, including metallic, glossy, and textured effects, catering to diverse design preferences in the automotive industry.

Precision Tube Laser Cutting

When considering precision tube laser cutting as a custom steel tube service in the automotive industry, it is essential to prioritize accuracy and clean cuts to ensure the safe functioning of finished assemblies.

Precision tube laser cutting offers distinct advantages in automotive tube fabrication, such as the ability to execute intricate tube bending techniques and provide various tube finishing options.

The process enables the creation of custom tube solutions that meet the specific requirements of automotive designers, ensuring optimal performance and fit.

By leveraging precision tube laser cutting, manufacturers can achieve a high degree of dimensional accuracy and repeatability, resulting in superior quality components for aftermarket automotive parts.

This advanced technology plays a pivotal role in enhancing the efficiency and effectiveness of custom steel tube services in the automotive industry.

Frequently Asked Questions

How Do Automotive Custom Tubes Contribute to Vehicle Performance and Efficiency?

Vehicle customization involves performance enhancement and efficiency improvement through custom tube fabrication. This trend in the automotive industry leverages durable materials and precise engineering to optimize exhaust systems, frame integrity, and overall vehicle performance.

What Are the Specific Materials Used for Custom Tubes in the Automotive Industry and How Do They Compare in Terms of Durability and Corrosion Resistance?

In the automotive industry, material selection for custom tubes is crucial. Durability comparison and corrosion resistance are essential factors in enhancing automotive performance. Materials such as stainless steel, aluminum, titanium, and copper-based alloys offer high durability and corrosion resistance, ensuring longevity and optimal performance.

Can You Provide Examples of Specific Automotive and Transport-Related Applications That Utilize Custom Tubing Components?

Custom tubing applications in automotive performance include exhaust systems, structural support in racing cars, and motorcycle customization. Materials like stainless steel and aluminum offer durability and corrosion resistance. Steel tube services for bending, cutting, and galvanizing ensure precise fabrication.

What Are the Advantages of Using Tubing in Automotive and Transport Applications Compared to Traditional Pipes?

The advantages of using tubing in automotive and transport applications, compared to traditional pipes, include improved performance and efficiency. Custom tubing materials and services, such as precision tube laser cutting, ensure optimal production and quality.

What Custom Steel Tube Services Are Available for the Automotive Industry and How Do They Contribute to the Production of Aftermarket Automotive Parts?

Custom tube bending, precision fabrication, and tube assembly services are available for the automotive aftermarket industry. These services contribute to the production of aftermarket automotive parts by providing performance enhancement through tailored and high-quality steel tubing solutions.

Conclusion

In conclusion, automotive custom tubes play a crucial role in optimizing vehicle performance and structural support in the automotive and motorsports industries.

The materials used, such as stainless steel, aluminum, titanium, and copper-based alloys, provide durability and corrosion resistance.

The custom steel tube services offered by USA-owned and operated suppliers ensure prompt deliveries and exceptional customer support.

Overall, the use of custom tubes in automotive applications is indispensable for achieving unparalleled performance and precision.