Selecting the right dimension of carbon steel pipe involves evaluating factors like diameter, wall thickness, and ASTM specifications. Take into account project requirements, pressure ratings, and end connections. Seek advice from professionals and adhere to industry standards. To guarantee optimal performance, tailor the pipe size to your specific needs. Consulting suppliers like Totten Tubes for customized solutions can enhance efficiency. Proper selection promises seamless integration into your system. Understanding unique specifications and applications is vital for successful installations. Make informed decisions to enhance functionality and performance.

Carbon Steel Pipe Sizes & Specifications

When selecting the appropriate carbon steel pipe for a project, understanding the sizes and specifications is crucial for ensuring structural integrity and efficiency. Carbon steel pipes come in various sizes, ranging from 1/8 inch to 48 inches in diameter, with different wall thicknesses to accommodate specific project requirements.

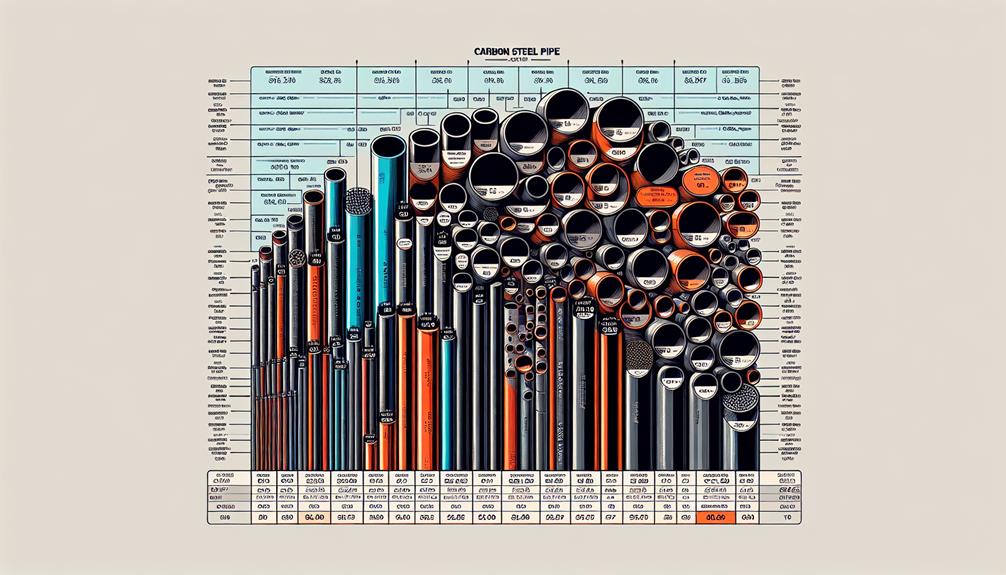

Common specifications for carbon steel pipes include ASTM A53 for general applications, ASTM A106 for high-temperature services, and API 5L for transportation of oil and gas. It is essential to take into account factors such as pressure rating, material composition, and end connections when choosing the right carbon steel pipe for a project.

Consulting with industry professionals and referring to relevant standards can help in making informed decisions regarding pipe sizes and specifications.

What are the project requirements for different sizes of carbon steel pipe?

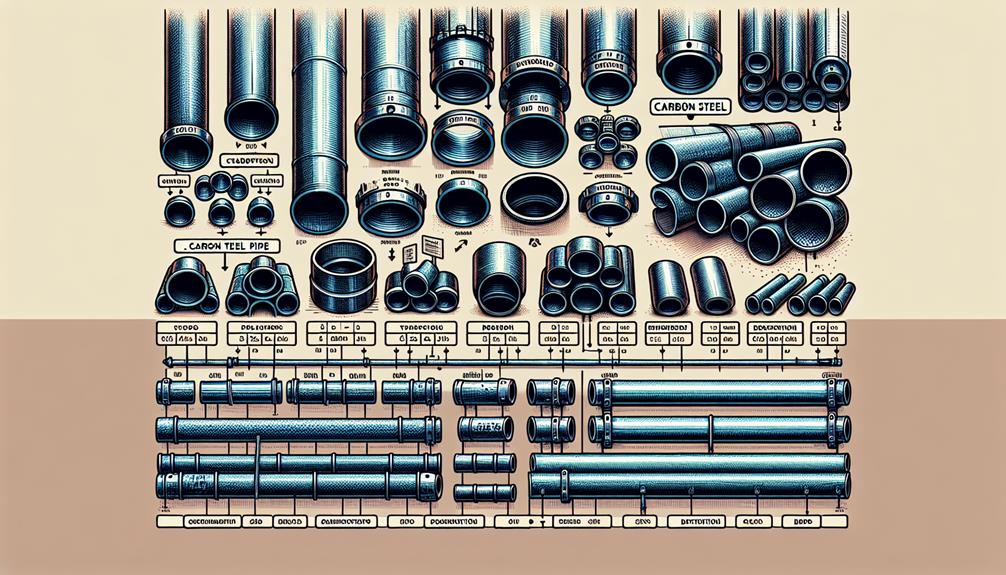

To determine the project requirements for different sizes of carbon steel pipe, thorough consideration of structural specifications and intended applications is essential. For rectangular structural steel tubing, such as A500B HSS and A500C HSS, with varying yield and tensile strengths, the usage in construction projects like buildings, highways, and bridges necessitates precise sizing to meet load-bearing demands.

Mechanical steel rectangular tubing, like A513 Type 1, is vital for support structures in mechanical applications like farm equipment and household appliances, requiring specific dimensions to guarantee functionality and durability. Understanding the unique specifications of each size and grade is paramount to selecting the appropriate carbon steel pipe for diverse project needs.

Contacting suppliers like Totten Tubes for tailored solutions and detailed information is recommended.

Common Carbon Steel Pipe Size Specifications and Applications

Common Carbon Steel Pipe Size Specifications and Applications involve a thorough understanding of the diverse range of options available for customization. This customization allows for meeting specific project requirements efficiently.

Offers size customization options

Size customization options for carbon steel pipes offer tailored solutions to meet specific project requirements, ensuring precise and efficient applications in various industries. By providing the flexibility to customize pipe sizes, manufacturers can cater to the unique needs of different projects, enhancing functionality and performance. This customization capability allows for the creation of pipes that fit seamlessly into existing systems or structures, reducing the need for extensive modifications or additional components. Here’s a breakdown of the benefits of size customization options:

| Advantages of Size Customization | ||

|---|---|---|

| 1. Precise Fit | 2. Enhanced Performance | 3. Streamlined Installation |

Carbon Steel Pipe Size Selection Form

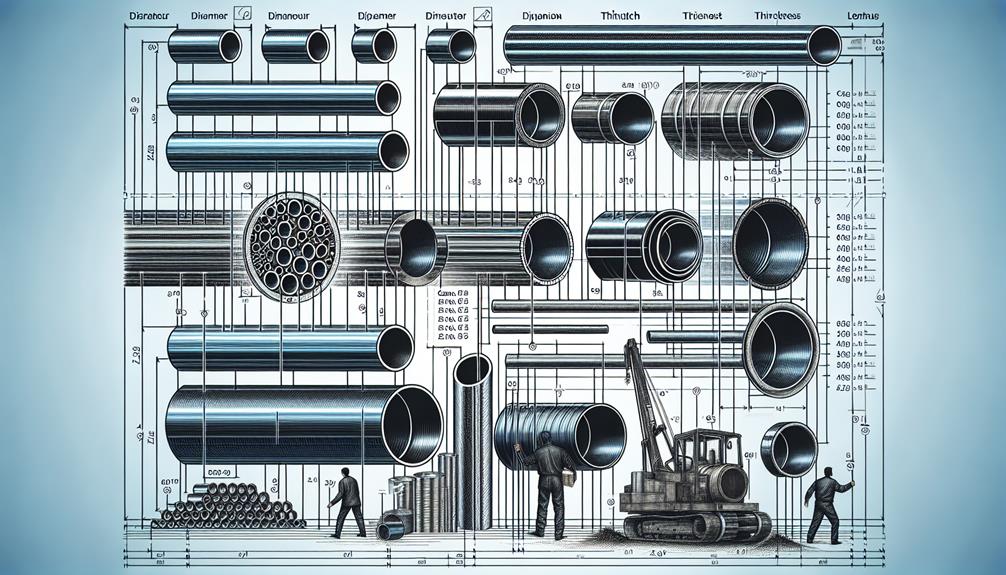

An essential aspect of selecting the appropriate carbon steel pipe for a specific application involves carefully considering the dimensions and specifications within the Carbon Steel Pipe Size Selection Form.

- Inside Diameter (ID): Measure the inner diameter to guarantee compatibility with the intended fluid flow.

- Wall Thickness: Select the appropriate thickness based on pressure and temperature requirements.

- Length Requirement: Determine the necessary pipe length for the installation process.

Choose the steel pipe that best suits your needs

When selecting the most appropriate steel pipe for your project requirements, thorough consideration of the dimensions and specifications is essential to guarantee peak performance and efficiency.

Whether you require rectangular structural steel tubing for construction projects or mechanical steel rectangular tubing for critical support structures, it is vital to assess factors such as yield strength, tensile strength, and specific application needs.

Rectangular structural steel tubing like A500B HSS or A1085 HSS offers varying characteristics suitable for different applications, while mechanical steel rectangular tubing, such as A513 Type 1, caters to specific mechanical requirements.

Frequently Asked Questions

What Are the Advantages of Using Carbon Steel Pipe Over Other Materials for Certain Projects?

Carbon steel pipes offer advantages like high strength, durability, and resistance to corrosion, making them ideal for various projects. Their cost-effectiveness, ease of maintenance, and recyclability further enhance their suitability for specific applications.

How Does the Thickness of Carbon Steel Pipe Affect Its Performance in Different Applications?

The thickness of carbon steel pipe greatly impacts its load-bearing capacity and resistance to corrosion in various applications. Thicker walls enhance durability but may increase weight and cost, necessitating a balance for best performance.

Are There Any Industry Standards or Regulations That Dictate the Use of Specific Sizes of Carbon Steel Pipe in Certain Projects?

Industry standards and regulations dictate specific sizes of carbon steel pipe for diverse projects. Compliance guarantees structural integrity, safety, and performance. Adhering to these standards is vital for meeting project requirements and guaranteeing seamless integration within various applications.

What Factors Should Be Considered When Determining the Appropriate Size of Carbon Steel Pipe for a Specific Project?

When determining the appropriate size of carbon steel pipe for a specific project, factors such as flow rate, pressure requirements, material compatibility, and environmental conditions must be considered. Consult with experts for precise sizing.

How Does the Cost of Different Sizes of Carbon Steel Pipe Compare, and How Does It Factor Into the Decision-Making Process for Selecting the Right Size?

The cost of various sizes of carbon steel pipe influences selection. Consider project requirements, budget constraints, and future maintenance costs. Analyze price per foot, installation expenses, and long-term durability to make an informed decision.

Conclusion

In the complex tapestry of project planning, the right size of carbon steel pipe is a vital thread that guarantees structural integrity and efficiency.

By carefully assessing factors such as working pressure, flow rate, and material compatibility, you can confidently select the best dimensions.

Let these considerations be your compass as you navigate the vast landscape of carbon steel pipe selection, guiding you towards a path of project success and longevity.