When selecting the appropriate square steel pipe, consider specific requirements and applications. Evaluate material for strength and durability. Assess size compatibility with project specifications. Verify surface finish for peak performance. Confirm weight capacity for loads. Guarantee these key factors align for peak performance.

Key Takeaways

- Consider specific requirements and applications for precise selection.

- Evaluate material for strength, durability, and corrosion resistance.

- Assess size compatibility with project specifications.

- Verify surface finish requirements for optimal performance.

- Confirm weight capacity to support anticipated loads.

How to choose the right square steel pipe for you

When selecting the appropriate square steel pipe for your project, consider the specific requirements and applications that align with your structural or mechanical needs. Begin by carefully evaluating the material selection to guarantee it meets the desired strength and durability standards for your application.

Size considerations play a critical role in determining the compatibility of the square steel pipe with your project specifications. Additionally, assess the surface finish requirements to ensure peak performance and longevity.

Confirm that the chosen square steel pipe is suitable for the intended application to prevent any structural or mechanical issues. Finally, verify the weight capacity of the pipe to confirm it can withstand the anticipated loads without compromising safety or integrity.

Customized services offered by brands

Metal Special offers customized carbon steel square tubing to suit specific requirements. They focus on providing rare sizes that may be hard to find elsewhere. Their personalized services cater to unique needs, ensuring exact tubing dimensions for your project.

When standard options fall short, Metal Special steps in to deliver tailored solutions for steel tubing needs.

Metal Special can provide carbon steel square tubing to fit your needs

With customized services offered by various brands, finding the right carbon steel square tubing to meet your specific needs is made easier than ever. Here are three key factors to ponder when selecting your tubing:

Material Selection: Confirm the tubing material aligns with your project requirements for strength and durability.

Strength Requirements: Determine the level of strength needed based on the application to withstand intended loads.

Corrosion Resistance: Evaluate the tubing’s ability to resist corrosion over time, especially if exposed to harsh environments.

Metal Special is available in rare sizes

Available in uncommon dimensions, Metal Special’s square steel tubing stands out for its rare sizes among the offerings provided by various brands. If you require unique dimensions that aren’t commonly found, Metal Special’s custom fabrication services can cater to your needs.

They specialize in uncommon sizes, making them a go-to choice for special orders requiring precise and rare specifications. With Metal Special, you can confidently place special orders knowing that they have the capability to provide exactly what you need.

Whether your project demands specific measurements that are hard to come by, Metal Special’s dedication to offering rare sizes guarantees that you get the right square steel tubing for your unique requirements.

The use of carbon steel square tube

When contemplating the utilization of carbon steel square tubing, you benefit from its exceptional strength and durability in various structural applications. Its high tensile strength and resistance to wear and tear make it a dependable choice for demanding projects.

The versatility of carbon steel square tubing guarantees it can meet the demands of a wide range of construction and industrial applications.

Advantages of carbon steel square tube

Carbon steel square tube stands out as a reliable and versatile choice for a wide range of structural and mechanical applications due to its high strength-to-weight ratio and durability.

When considering the advantages of carbon steel square tubes, you’ll find that:

Corrosion resistance: Carbon steel square tubes exhibit good resistance to corrosion, making them suitable for outdoor and harsh environments.

Strength properties: With excellent strength properties, carbon steel square tubes provide structural integrity and support in various applications.

Welding capabilities: Carbon steel square tubes can be easily welded, allowing for secure and efficient connections in fabrication processes.

These factors, combined with the cost efficiency and versatile applications of carbon steel square tubes, make them a preferred choice for many engineering projects.

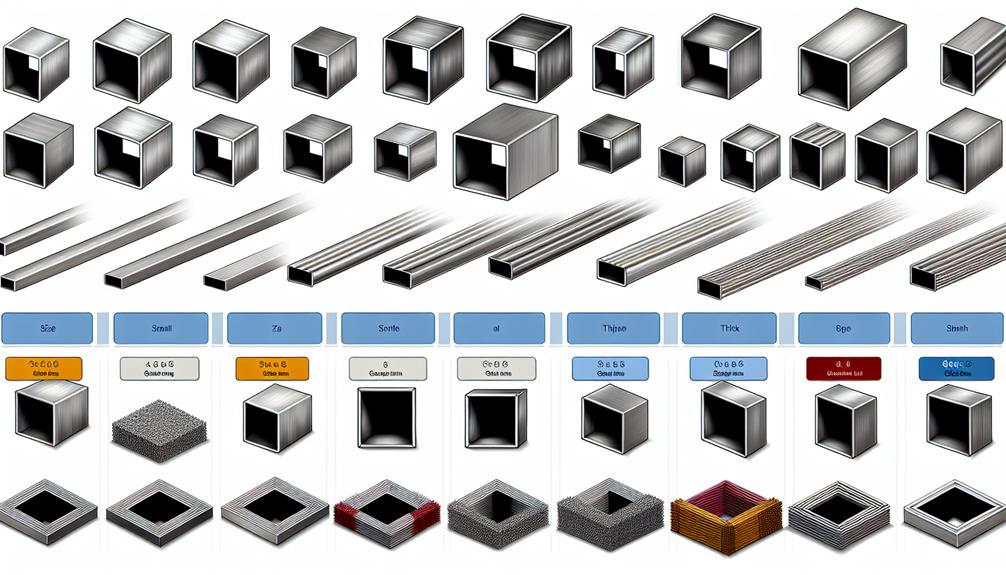

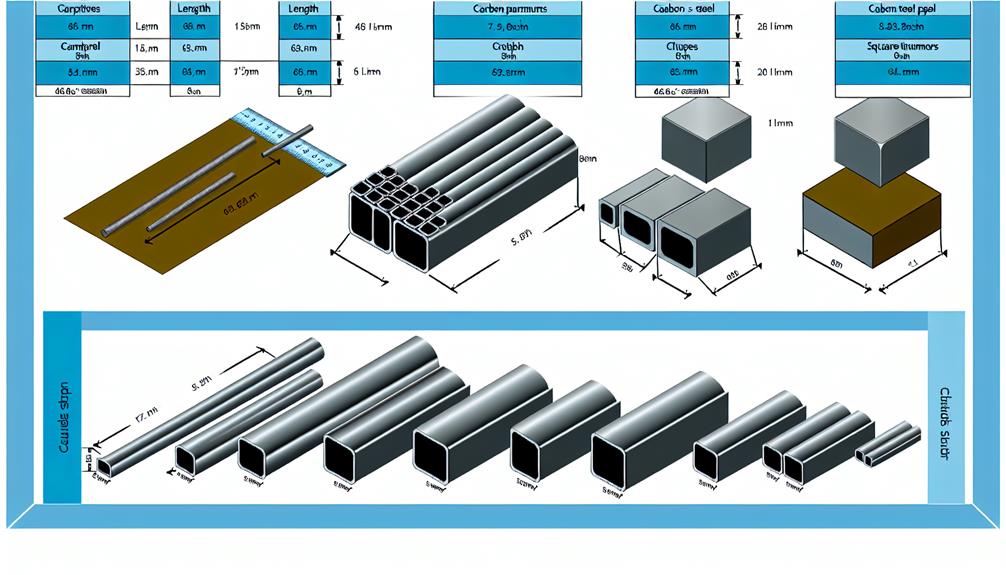

Dimensional parameters of carbon steel square

One essential aspect to keep in mind when selecting square steel tubing is understanding the dimensional parameters that characterize the various options available. The material thickness plays a critical role in determining the load capacity of the carbon steel square tube. Thicker walls generally result in higher load-bearing capabilities.

Additionally, considering the welding techniques required is important to guarantee proper joint integrity and strength. Corrosion resistance can be influenced by the surface finish of the square tube, making it crucial to choose finishes that offer adequate protection against environmental factors.

When evaluating dimensional parameters, paying close attention to these factors will help you select the most suitable carbon steel square tube for your specific needs.

Frequently Asked Questions

What Are the Benefits of Opting for Mechanical Steel Square Tubing Over Structural Steel Square Tubing for Certain Applications?

Opting for mechanical steel square tubing over structural offers cost efficiency and durability in dynamic applications. Customization options and versatility cater to specific needs. Its strength and lower weight provide precision and tight tolerance. Enhanced machinability and aesthetics are key benefits.

How Does the Production Process Differ Between A500B FR and A1085 HSS Structural Steel Square Tubing Options?

When comparing the production process of A500B FR and A1085 HSS, note that A500B FR is typically welded using traditional techniques, suitable for high temperature applications. A1085 HSS offers enhanced material compatibility and corrosion resistance, prioritizing production efficiency.

Are There Any Specific Industry Standards or Regulations That Govern the Use of A513-1 BLACKKOTE Mechanical Steel Square Tubing?

Industry standards and regulations dictate the use of A513-1 BLACKKOTE mechanical steel square tubing. Compliance requirements guarantee adherence to material specifications. Quality control measures are essential to meet standards for this type of tubing.

Can Mechanical Steel Square Tubing Be Easily Welded to Other Materials, Such as Aluminum or Stainless Steel?

When welding mechanical steel square tubing, consider its welding compatibility with materials like aluminum or stainless steel. Assess strength comparison, corrosion resistance, and temperature limits. Verify material versatility for precise applications.

Are There Any Special Considerations to Keep in Mind When Selecting a Square Steel Tubing Size for High-Temperature or Corrosive Environments?

When selecting a square steel tubing size for high-temperature or corrosive environments, consider factors like material selection, environmental conditions, and size considerations. Guarantee high temperature resistance and corrosion protection by choosing wisely.

Conclusion

Just as a master craftsman selects the perfect tool for each task, choosing the right square steel tubing is essential for the success of your project.

With Totten Tubes‘ vast inventory and customized services, you can be confident in finding the ideal solution tailored to your unique needs.

Trust in the strength and precision of carbon steel square tubing to support your construction or mechanical endeavors.

Choose wisely, choose Totten Tubes.